General Information

Helping a member today assemble a fuel system, the question came up on how to properly prepare and tighten our different plumbing joints. This brief article will answer those questions.

Pipe Threads

Pipe threads seal by metal-to-metal contact of the thread faces. But it is a balancing act - too loose and it will leak, but too tight and you may crack the boss it is threaded into. The correct engagement can be related to the number of turns after making up the joint 'hand tight'. Before tightening, the joint should be prepped using either a Teflon tape or Teflon paste.

- Apply 1-1/2 but no more than 2 wraps of teflon tape on the male thread, wrapping it clockwise as you look at the end of the fitting. The tape should be installed leaving the first thread bare. If using teflon paste, add it to the threads, wiping it into the root of the threads, again leaving the first thread exposed. The reason for the exposed end is to prevent contamination of the joint with tape or compound.

- Thread the joint together, tightening it as much as you can using your fingers.

- Mark the two pieces with a felt-tip pen line so you can determine how many turns you will apply.

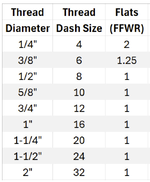

- This chart shows the recommended number of turns required to achieve a tight joint. If the fitting must be pointed in a particular direction, never back off the fitting to get the direction. It must be tightened til it points in the desired direction.

37 Degree fittings (AN or JIC)These fittings seal by metal-to-metal contact of the flare faces. Under-tightening will cause the fitting to leak and likewise, too tight will deform the fitting and cause it to leak. The preferred method to tighten these is to thread the fittings together using a wrench to the point where the joint just starts to tighten (about 25 in/lbs). This is called "flats from wrench resistance or 'FFWR'" then tighten a specific number of 'flats'. DO NOT use any Teflon tape or compound on this style joint. Clean both faces with a dry rag.

- Thread the joint together, holding the line or hose aligned with the fitting. Use a wrench to begin tightening the joint.

- Using a felt-tip marker, place a line across the joint from one wrench flat to the opposite one so you can tell how many turns are made

- Tighten the fitting the number of flats indicated in the chart. One flat is 1/6 of a turn.

When tight, add a third mark with the pen to indicate the tightened point as a visual reference. If the joint is ever loosened, it must be retightened to this point or just past it.

Caution: Over-tightening can deform the flares and will cause the joint to leak. If the joint is leaking and can not be tightened, the fitting can be reused by adding a specially formed conical washer available from Summit Racing. Do a Google search for "AN Fitting Conical Seal Kit"